Uncovering the Secrets of Wet Wipe Raw Materials

Wet wipes are ubiquitous in modern life, providing convenience and hygiene for a range of applications, from personal care to industrial cleaning. Despite their widespread use, the materials used to manufacture wet wipes remain less understood by the general public. Exploring these raw materials reveals not only the complexity of wet wipe production but also their impact on performance, cost, and sustainability.

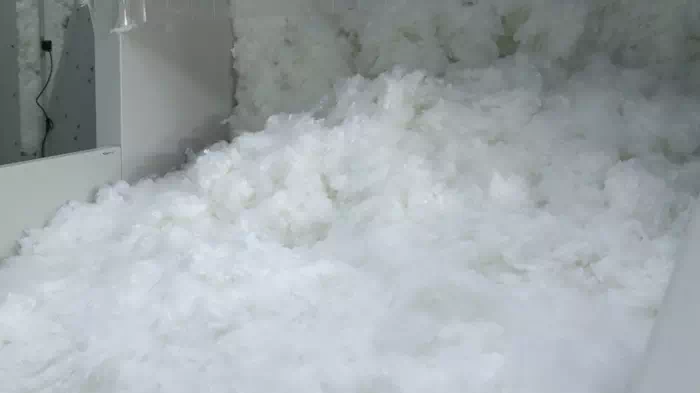

The primary component of wet wipes is the substrate or base material, which determines the wipe’s texture, strength, and absorbency. Most wet wipes are made from nonwoven fabrics, typically composed of polyester, viscose, or a blend of the two. Polyester adds durability and tear resistance, while viscose enhances softness and absorbency. Some manufacturers are shifting toward sustainable options, such as bamboo or cotton, to reduce environmental impact.

To cater to specific needs, manufacturers frequently include additives in their wet wipes. Antibacterial agents, such as benzalkonium chloride, make the wipes suitable for sanitization purposes, while fragrance or essential oils enhance the sensory experience. In baby wipes, soothing agents like chamomile or calendula are added to prevent irritation on sensitive skin.

Some wet wipes also feature biodegradable polymers or natural binders to improve their environmental compatibility. These materials help balance performance requirements with the growing demand for eco-friendly products.

The raw materials behind wet wipes play a critical role in determining their performance, cost, and environmental impact. By understanding the components and innovations in this industry, consumers can make informed choices that align with their values, whether prioritizing skin safety, hygiene, or sustainability. As technology advances and sustainability remains at the forefront, the secrets of wet wipe raw materials will continue to shape the future of this essential product.