Understanding the Essential Raw Materials for Wet Wipes

Wet wipes have become an indispensable part of daily life, offering convenience and hygiene in one compact package. From personal care to industrial applications, their uses are diverse and ever-growing. However, the effectiveness and quality of wet wipes largely depend on the raw materials used in their production. Understanding these materials can provide insights into their functionality, sustainability, and safety.

Understanding the Essential Raw Materials for Wet Wipes

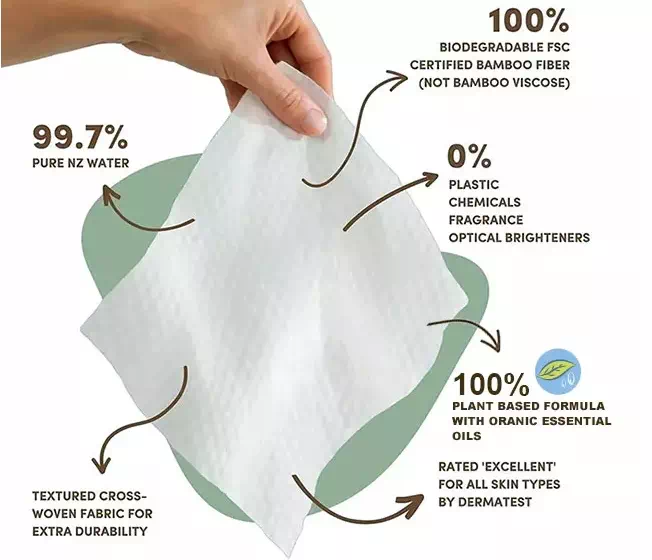

The foundation of any wet wipe is its base material, typically made from nonwoven fabrics. These fabrics are chosen for their durability, softness, and absorbency. Commonly used fibers include polyester and polypropylene for their strength and cost-effectiveness, viscose for its natural absorbency and biodegradability, and cotton for its hypoallergenic properties. Manufacturers often blend these fibers to achieve a balance of strength, softness, and cost, ensuring the wipes meet specific usage requirements.

The liquid solution impregnated into wet wipes determines their specific purpose. Water, as the primary ingredient, must be purified to prevent contamination. Additional components such as mild cleansing agents, moisturizers like glycerin or aloe vera, and preservatives are carefully selected to ensure safety and effectiveness. For specialized uses, disinfectants or antibacterial agents like alcohol are added, while fragrances and essential oils enhance the user experience. All these elements must be balanced to create a product that is both functional and skin-friendly.

The packaging of wet wipes is also crucial in maintaining their quality and usability. Plastic films and aluminum laminates are commonly used to protect the wipes from drying out or contamination. Resealable lids or flip-tops are designed to ensure convenience and freshness. With growing environmental awareness, manufacturers are adopting sustainable practices, such as using biodegradable fibers like bamboo, reducing chemical additives in favor of natural solutions, and developing recyclable or reusable packaging.